Machine Type: Granulator

Noisy: >75dB

Working Time: 45~90min

Application: Solid dosage granulation production line

The process flow consists of high speed wet mixing granulator, wet mill, fluid bed dryer, dry mill, vibrating sifter, mixer, vacuum feeder and so on.

Main Features

1. The newly designed solid preparation production line adopts closed transportation mode to ensure that granulation and drying are completed in the same purification chamber, avoiding secondary pollution, making the granulation and drying process more scientific and reasonable.

2. Users can adjust the corresponding equipment according to the actual capacity and dosage form of customers, so that the production process can achieve the optimal configuration to ensure the continuity and stability of production.

3. The user can store, collect and print the technical data of the wet granulation system and the fluid drying system through the man-machine interface.

4. The main menu of the control system can reflect the working status and data statistics in real time, and reflect the equipment failure through the fault self-diagnosis system and alarm record, so that the production process can be fully automatic and ensure the stability of the process.

5. Vacuum drug feeder and pharmaceutical elevator have high automatic production capacity, which can replace traditional manual operation and correspondingly reduce labor intensity and dust pollution.

6. In-situ cleaning can be configured at multiple different points according to user requirements, making CIP more reliable.

| Model | FLG5 | FLG30 | FLG60 | FLG120 | FLG300 | FLG500 |

| LD100 | LD200 | LD300 | LD800 | LD1200 | ||

| ZS350 | ZS515 | ZS800 | ZS1000 | ZS1200 | ||

| ZKS1 | ZKS2 | ZKS2 | ZKS4 | ZKS5 | ||

| GHL15 | GHL100 | GHL200 | GHL400 | GHL1000 | GHL1500 | |

| GZL80 | GZL80 | GZL180 | GZL250 | GZL300 | GZL450 | |

| FG5 | FG30 | FG60 | FG120 | FG300 | FG500 | |

| ZKS1 | ZKS1 | ZKS2 | ZKS4 | ZKS5 | ||

| NTF100 | NTF200 | NTF300 | NTF800 | NTF1000 | ||

| LD100 | LD200 | LD300 | LD800 | LD1200 | ||

| Capacity/KG | 5 | 30 | 60 | 120 | 300 | 500 |

♦Pharmaceutical industry: Rotary tablet press in the pharmaceutical industry is widely used in the manufacture of tablets, capsules and other solid preparations.It is capable of pressing raw materials such as medicinal powders into tablets of consistent shape, weight and hardness, ensuring the quality and stability of the medication.

♦Food industry: In the food industry, rotary tablet presses are often used to manufacture solid foods such as candy, chewing gum and vitamin tablets. It can press food raw materials into products of various shapes and flavors, and ensure product quality and consistency.

♦Chemical industry: Rotary tablet press is used in the chemical industry to manufacture chemical products, such as ceramic sheets, composite materials, powder metallurgy products, etc. It can press chemical raw materials to make them have a certain shape, density and strength.

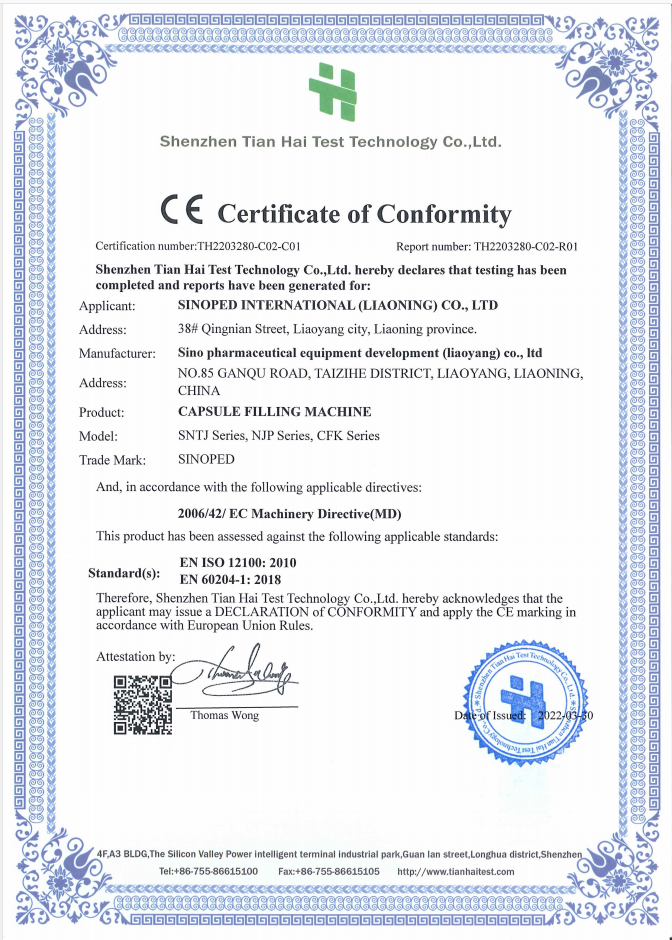

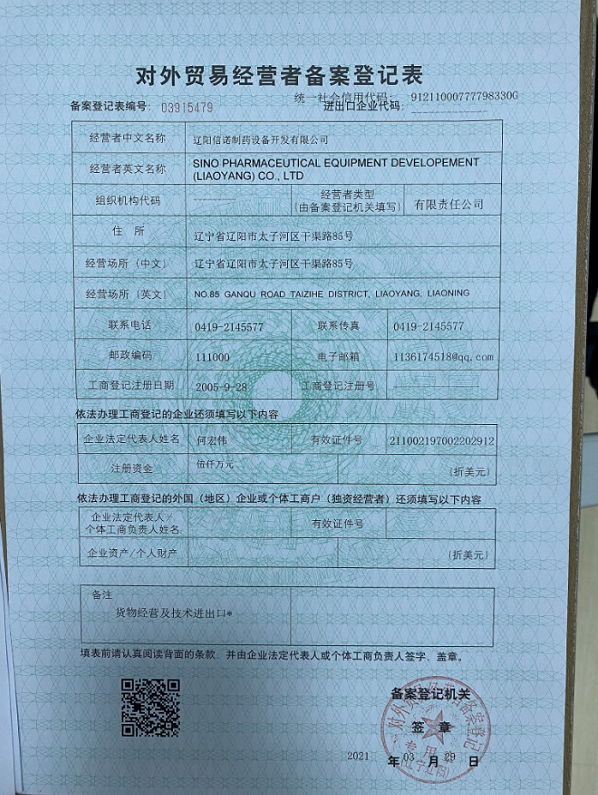

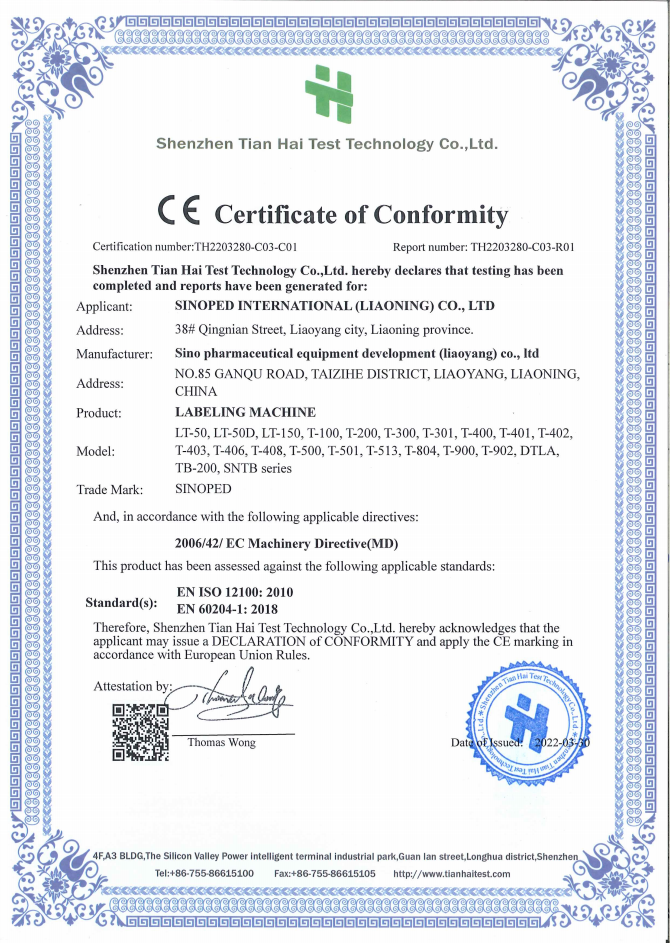

Certifications and Patents

Get In Touch With Us

The first thing we do is meeting with our clients and talk through their goals on a future project.

During this meeting, feel free to communicate your ideas and ask lots of questions.